Cargo Securing for Roll Trailers (MAFIs)

The Club continues to receive claims in respect of cargo shifting due to inadequate securing where roll trailers have been used. This can either be inadequate securing of the load to the trailer or inadequate securing of the trailer to the vessel, or a combination of both.

Common failings found include:

- The angle of lashings between the vessel and the cargo to prevent either tilting or sliding, being outside of the effective range.

- No lashings between the cargo and the trailer.

- No lashings between the cargo and the vessel to prevent tilting.

- Deficient lashing strength due to insufficient number of lashings or inadequate SWL of the lashing materials or excessively worn lashings.

- Loose stow of cargo on the roll-trailer.

- No account taken of the centre of gravity of the loaded roll-trailer which can often be high above deck level.

- The use of “silly-loop” lashings (loop lashings with their ends fastened to either side of the trailer) – these do not provide any direct securing effect.

- The use of “Friction Loop” lashings, being lashings passed from one side of the trailer to the other, over the cargo. Although such lashings can provide some enhanced friction between the cargo and the trailer, the cargo can move about under the lashings.

In addition to avoiding the above commonly found issues, the following publications provide guidance on lashing / securing and the onboard stowage and securing should follow the guidance given therein:

- The Cargo Securing Manual (CSM) of the vessel.

- IMO/ILO/UNECE Code of Practice for Packing of Cargo Transport Units (CTU Code) - Annex 7.

- IMO Code of Safe Practice for Cargo Stowage and Securing (CSS Code).

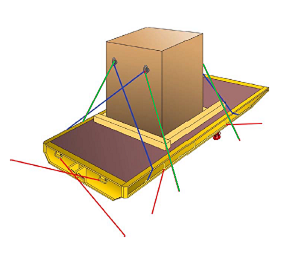

The above image shows the correct lashings method – note cargo is secured to the roll-trailer (blue lines) and the roll-trailer is secured to the deck (red lines) to prevent sliding. Additionally, green lashings are used to prevent tipping of the cargo unit.

Members requiring further guidance should contact the Loss Prevention department.